|

|||||||||

|

|

|

|

||||||

OTTAWA, Canada- TheNewswire – Feb. 17, 2023 – Stria Lithium Inc. (TSXV:SRA) (OTC:SRCAF) an emerging resource exploration company developing Canadian lithium reserves to meet legislated demand for electric vehicles and their rechargeable lithium-ion batteries, is pleased to announce promising assay results from the first two drill holes at depth on the Pontax Lithium Project (“Pontax”) in the James Bay region of Québec, Canada.

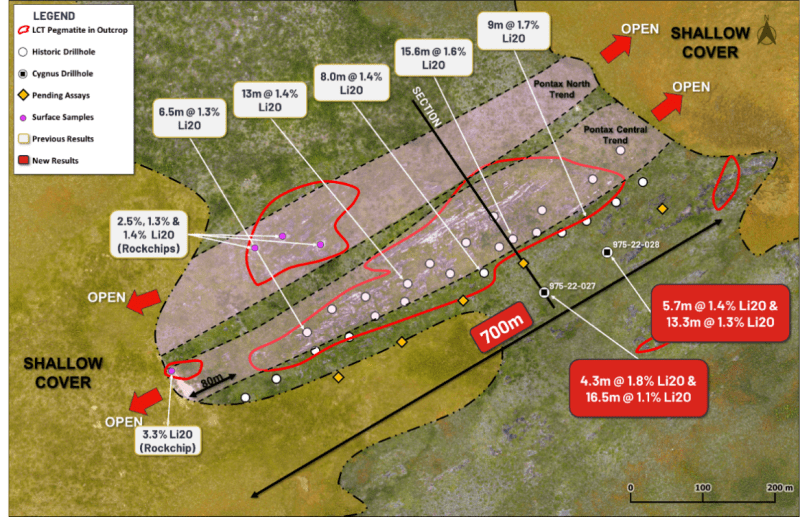

Assays include 10.2 m (true width) at 1.34% Li2O, and a doubling of the depth of known mineralization to 230m. These results further confirm previous exploration activities on the site and are only the first results of 14 holes drilled to date, totalling 3,858 metres, as part of an aggressive 15,000-metre definition and exploration drilling program now under way on Stria’s Pontax property in the west-central Eeyou Istchee James Bay (EIJB) Territory. A winter road has been opened from the main highway to the Pontax site, and mutiple drill rigs are now on site with the aim of establishing a maiden resource by mid–2023. Assays from the remaining 12 holes are currently pending at the laboratories.

The drilling program at Stria’s Pontax property is being financed and conducted by Stria’s project partner, Cygnus Gold Ltd. of Australia, and has been designed to systematically step out from known mineralisation at Pontax Central – an extensive spodumene-bearing pegmatite swarm which outcrops over 700m of strike.

Significant intersection results from the latest drilling include;

-

-

DDH975-22-027:

-

2.82 m* (4.3m of core length) @ 1.84% LiO** at a depth of 158 metres(from 227.6m to 231.9m)

-

6.04 m* (9.21m core length) @ 1.44% LiO** at a depth of 172 metres (from 247.1m to 256.3m)

-

Five (5) minor intervals of true width between 1.51m* and 2.02m* @ 0.84% to 1.46% LiO**

-

Cumulative true thickness of mineralized dyke of 21.4 metres

-

-

DDH975-22-028:

-

3.44 m* (5.7m of core length) @ 1.35% LiO** at a depth of 144 metres (from 194.3m to 200.0m)

-

8.54 m* (13.3m of core length) @ 1.34% LiO** at a depth of 212 metres (from 300.2m to 313.5m)

-

-

-

-

-

Three (3) minor intervals of true width between 1.08m* and 1.55m* @ 0.67% to 0.82% LiO**

-

Cumulative true thickness of mineralized dyke of 17.9 metres

-

-

*: True thickness, assuming the dykes are dipping -85o to the NNW

**: Weighted average using a cut-off grade of 0.5% Li2O on spudumene dyke only, excluding lithium bearing wallrock (FeO > 5%), a minimum true thickness of 1 metre, no external dilution, and wallrock internal dilution set at 0% Li2O.

Drilling was conducted with a single heliportable rig by RJLL Drilling Co. from Rouyn-Noranda and supervised by IOS Services Geoscientifiques Inc. Collar location was measured with a high resolution GPS Geode device, while downhole deviation was measured with the use of a Reflex device. Core, NQ in diameter, has been logged on site and expedited by road carrier to IOS facilities in Saguenay, Quebec, for sampling and storage. Core samples were cut in half with a diamond saw, tagged and bagged to be shipped to SGS Lakefield laboratory by road carrier for preparation. Core samples were crushed (75% <2mm) and pulverized (85% <75μm). Assaying has been conducted by SGS Burnaby with the use of ICP-OES and ICP-MS after sodium peroxide fusion (GE_ICM91A50). SGS-Canada is an ISO/IEC 17025 accredited laboratory. Quality control has been monitored by an IOS certified chemist through the insersion of 7 sample blanks, 7 preparation blanks, 5 certified reference material Oreas-147, 4 certified reference material Oreas-148 and 5 certified reference material Orea-149, for a total of 28 insertions (15%).

Dean Hanisch, CEO of Stria Lithium, said today: “We are excitied to be finally getting an aggressivce drilling program at depth under way, and are very encouraged by the promising results of the first two holes of 14 drilled to date. The winter road is open and providing economical access to several additional heavy drill rigs. We look forward to reporting more assay results as they become available.”

The latest drilling has stepped out 50m to 100m below existing mineralisation to a vertical depth of 230m, effectively doubling the depth of known mineralisation which remains open in all directions.

Figure 1: Plan view of Pontax Central with the location of all drilling to date. Highlighting recent significant intersections including 8.54m @ 1.34% Li2O and 6.04 @ 1.44% Li2O

Figure 2: Cross section though Pontax Central looking towards the NE, showing both historic drillholes and the recent deeper drillholes completed by Cygnus with results recived to date, including 4.3m @ 1.8% Li2O and 16.5m @ 1.1% Li2O. Interval length expressed as true thickness and depth as vertical depth. The recent drilling is the deepest drilling on the project to date stepping out over 100m from exisiting drilling with mineralisation remaining open in all directions.

Stria Lithium (TSX-V: SRA) is an emerging resource exploration company developing Canadian lithium reserves to meet legislated demand for electric vehicles and their rechargeable lithium-ion batteries.

Lithium is a rare metal and an indispensable component of rechargeable lithium-ion batteries, one of the safest and most efficient energy storage technologies available today, used in everything from cellphones and power tools to electric cars and industrial-scale energy storage for renewable power sources such as wind and solar generation.

Stria’s Pontax Lithium Project covers 36 square kilometres, including 8 kilometres of strike along the prospective Chambois Greenstone Belt. The region, known as the Canadian “Lithium Triangle,” is one of only a few known sources of lithium available for hardrock mining in North America.

Stria’s Pontax property is situated close to an industrial powerline and a major paved highway, about 310 km north of the North American rail network leading to industrial heartland.

As momentum builds for the green energy revolution and the shift to electric vehicles, governments in Canada and the U.S. are aggressively supporting the North American lithium industry, presenting the industry and its investors with a rare, if not unprecedented, opportunity for growth and prosperity well into the next decade and beyond.

Cygnus Gold is committed to fully funding and managing the current two-stage exploration and drilling program up to $10 million at Stria’s Pontax property, and will also pay Stria up to $6 million in cash. In return, Cygnus may acquire up to a 70% interest in the property.

Stria is committed to exceeding industry’s environmental, social and governance standards. A critical part of that commitment is forging meaningful, enduring and mutually beneficial relationships with the James Bay Cree Nation (Eeyouch), and engaging openly and respectfully as neighbors and collaborators in an exciting project with the potential to create lasting jobs and prosperity for Eeyou Istchee and its people.

The technical content disclosed in the current press release was reviewed and approved by Réjean Girard, P.Geo and president of IOS Services Geoscientifiques Inc, a qualified person as defined under National Instrument NI-43-101.

For more information about Stria Lithium and the Pontax Lithium project, please visit https://strialithium.com

Follow us on:

-

Twitter@StriaLithium

-

Instagram@strialithium

For more information on Stria Lithium Inc., please contact:

Dean Hanisch

CEO Stria Lithium

+1(613) 612-6060

Kimberly Darlington

Communications, Stria Lithium Inc.

514-771-3398

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the accuracy or adequacy of this release.

Cautionary Note Regarding Forward-Looking Information

Except for statements of historical fact, this news release contains certain “forward-looking information” within the meaning of applicable securities law. Forward-looking information is frequently characterized by words such as “plan”, “expect”, “project”, “intend”, “believe”, “anticipate”, “estimate” and other similar words, or statements that certain events or conditions “may” or “will” occur. Although we believe that the expectations reflected in the forward-looking information are reasonable, there can be no assurance that such expectations will prove to be correct. We cannot guarantee future results, performance or achievements. Consequently, there is no representation that the actual results achieved will be the same, in whole or in part, as those set out in the forward-looking information.

Forward-looking information is based on the opinions and estimates of management at the date the statements are made and are subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those anticipated in the forward-looking information. Please refer to the risk factors disclosed under our profile on SEDAR at www.sedar.com. Readers are cautioned that this list of risk factors should not be construed as exhaustive.

The forward-looking information contained in this news release is expressly qualified by this cautionary statement. We undertake no duty to update any of the forward-looking information to conform such information to actual results or to changes in our expectations except as otherwise required by applicable securities legislation. Readers are cautioned not to place undue reliance on forward-looking information.

The technical aspects of the current press release have been reviewed by Réjean Girard, géo. (QC), President of IOS Services Géoscientifiques Inc., a consultant to the Company and a Qualified Person as defined under National Instrument (NI) 43 – 101 Standards of Disclosure for Mineral Projects has reviewed and approved the technical content of this news release.

APPENDIX A – Drillholes with Results

Coordinates given in UTM NAD83 (Zone 18)

|

Hole ID |

Easting |

Northing |

RL |

Azimuth |

Dip |

Depth |

|

975-22-027 |

362939 |

5754676 |

250 |

325 |

-50 |

309 |

|

975-22-028 |

363023 |

5754731 |

248 |

325 |

-50 |

333 |

APPENDIX B – Significant Intercepts

Significant intersections use a cut-off grade of 0.5% Li2O in pegmatite, no external dilution and internal dilution from wallrock accounted as 0%. Intercept lengths may not add up due to rounding to the appropriate reporting precision.

|

Hole ID |

From (m) |

To (m) |

Length (m) |

Depth (m) |

True width (m) |

Li2O % |

|

975-22-027 |

143.00 |

143.75 |

1.50 |

101.12 |

0.96 |

0.87 |

|

155.96 |

156.75 |

1.47 |

110.28 |

0.94 |

1.16 |

|

|

180.54 |

181.35 |

2.30 |

125.41 |

1.51 |

1.79 |

|

|

197.64 |

198.50 |

2.59 |

137.29 |

1.70 |

0.60 |

|

|

204.42 |

205.12 |

1.38 |

142.00 |

0.91 |

1.01 |

|

|

227.59 |

228.59 |

4.30 |

158.10 |

2.82 |

1.08 |

|

|

239.84 |

240.84 |

3.00 |

166.61 |

1.97 |

2.38 |

|

|

247.11 |

248.11 |

9.21 |

171.66 |

6.04 |

0.94 |

|

|

268.19 |

268.91 |

3.00 |

182.91 |

2.02 |

0.79 |

|

|

279.70 |

280.32 |

1.24 |

190.75 |

0.83 |

0.68 |

|

|

976-22-028 |

173.82 |

174.55 |

1.48 |

129.17 |

0.89 |

2.07 |

|

180.60 |

181.44 |

2.58 |

134.21 |

1.55 |

0.93 |

|

|

188.70 |

189.50 |

1.60 |

140.23 |

0.96 |

1.54 |

|

|

194.32 |

195.00 |

5.72 |

144.41 |

3.44 |

0.96 |

|

|

242.10 |

243.00 |

1.80 |

179.92 |

1.08 |

1.04 |

|

|

267.45 |

268.20 |

2.25 |

195.60 |

1.39 |

1.08 |

|

|

300.15 |

301.00 |

13.30 |

212.24 |

8.55 |

2.51 |

APPENDIX C

Pontax Project Drilling – 2012 JORC Table 1

Section 1 Sampling Techniques and Data

|

Criteria |

JORC Code explanation |

Commentary |

|

Sampling techniques |

Nature and quality of sampling (eg cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. |

|

|

Include reference to measures taken to ensure sample representivity and the appropriate calibration of any measurement tools or systems used. |

|

|

|

Aspects of the determination of mineralisation that are Material to the Public Report. In cases where ‘industry standard’ work has been done this would be relatively simple (eg ‘reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay’). In other cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (eg submarine nodules) may warrant disclosure of detailed information. |

|

|

|

Drilling techniques |

Drill type (eg core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc) and details (eg core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). |

|

|

Drill sample recovery |

Method of recording and assessing core and chip sample recoveries and results assessed. Measures taken to maximise sample recovery and ensure representative nature of the samples. Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. |

|

|

Logging |

Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. |

|

|

Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. |

|

|

|

The total length and percentage of the relevant intersections logged. |

|

|

|

Sub-sampling techniques and sample preparation |

If core, whether cut or sawn and whether quarter, half or all core taken. If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. For all sample types, the nature, quality and appropriateness of the sample preparation technique. Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. Measures taken to ensure that the sampling is representative of the in-situ material collected, including for instance results for field duplicate/second-half sampling. Whether sample sizes are appropriate to the grain size of the material being sampled. |

|

|

Quality of assay data and laboratory tests |

The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. |

|

|

For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. |

|

|

|

Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established. |

|

|

|

Verification of sampling and assaying |

The verification of significant intersections by either independent or alternative company personnel. |

|

|

The use of twinned holes. |

|

|

|

Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. |

|

|

|

Discuss any adjustment to assay data. |

|

|

|

Location of data points |

Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. |

|

|

Specification of the grid system used. |

|

|

|

Quality and adequacy of topographic control. |

|

|

|

Data spacing and distribution |

Data spacing for reporting of Exploration Results. |

|

|

Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity appropriate for the Mineral Resource and Ore Reserve estimation procedure(s) and classifications applied. |

|

|

|

Whether sample compositing has been applied. |

|

|

|

Orientation of data in relation to geological structure |

Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type. |

|

|

If the relationship between the drilling orientation and the orientation of key mineralised structures is considered to have introduced a sampling bias, this should be assessed and reported if material. |

|

|

|

Sample security |

The measures taken to ensure sample security. |

|

|

Audits or reviews |

The results of any audits or reviews of sampling techniques and data. |

|

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

|

Criteria |

JORC Code explanation |

Commentary |

|

|

Mineral tenement and land tenure status |

Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. |

|

|

|

The security of the tenure held at the time of reporting along with any known impediments to obtaining a licence to operate in the area. |

|

||

|

Exploration done by other parties |

Acknowledgment and appraisal of exploration by other parties. |

|

|

|

Geology |

Deposit type, geological setting and style of mineralisation. |

|

|

|

Drill hole Information |

A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes:

If the exclusion of this information is justified on the basis that the information is not Material and this exclusion does not detract from the understanding of the report, the Competent Person should clearly explain why this is the case. |

|

|

|

Data aggregation methods |

In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. |

|

|

|

Where aggregate intercepts incorporate short lengths of high-grade results and longer lengths of low-grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. |

|

||

|

The assumptions used for any reporting of metal equivalent values should be clearly stated. |

|

||

|

Relationship between mineralisation widths and intercept lengths |

These relationships are particularly important in the reporting of Exploration Results. If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg ‘down hole length, true width not known’). |

|

|

|

Diagrams |

Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. |

|

|

|

Balanced reporting |

Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. |

|

|

|

Other substantive exploration data |

Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples – size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. |

|

|

|

Further work |

The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. |

||

Copyright (c) 2023 TheNewswire – All rights reserved.